Using various international software packages, M-7 Technologies is equipped to service all modeling needs for reverse engineering and geometrical inspection projects. Our software packages are compatible with all of our precision measurement equipment which includes: portable CMMs (Coordinate Measuring Machine), a laser tracker, and laser scanners.

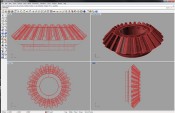

The typical process consists of compiling point cloud data through laser scanning and probing, building a polygonal mesh from the point cloud data, then creating a 3D model from the collected data. This process delivers reverse engineered models and drawings as well as color overlays and inspection reports used to compare the as-measured workpiece to parent design files.

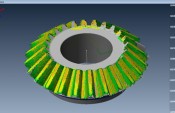

Laser Scanning measures an X, Y, and Z coordinate point for every reading taken of the subject workpiece – about 20,000 points per second. In the bevel gear example link there are over 3 million points! The first step to an accurate and precise 3D model is the point cloud data. Beginning with millions of measured points allows for extremely accurate 3 dimensional models to be constructed. Upon collecting point cloud data the information is then utilized to create a polygonal mesh. The mesh consists of a series of triangles each having specific vertices, edges and faces. In general this mesh is the start of transforming the scanned data into a 3D model.

The attached links provide project-specific examples of our 3D-modeling capability. Our services are employed by a wide array of industries, applications, and end users.